Stress

Concentration

|

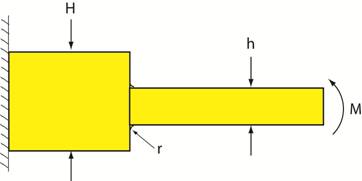

Example: Suppose the allowable

stress for the beam shown below is 90 MPa where H = 80 mm and h = 40 mm. Find the maximum allowable bending moment

when the radius, r, of the fillet welding the

two parts of the composite beam together is 8 mm and the thickness, t, of the composite beam is 8 mm. |

|

Strategy: Calculate the average bending stress in the

shaft using Mc/I for the smaller section of the beam. Then use the chart for bending of a

composite beam connected by fillet welds to find the stress

concentration factor, K. The stress concentration

factor, K, depends on the ratio of the depth of the

larger section, H, to the depth of the

smaller section, h, as well as the ratio of r, of the fillet weld to the depth, h, of the smaller

section. So these values need to be

determined. Finally apply K

= σmax / σave. For the data: D/d

= H/h = 2 and

r/d

= r/h =

8/40 = 0.2 So from the chart, the

stress concentration factor, K,

is 1.5 Now for the smaller

section, σave =

Mc/I where

c = h/2 = 20

mm and I

= (1/12) t h3 =

(1/12) (8)(40)3 mm4 σave =

Mc/I = M(20)/[(1/12)(8)(40)3] = 3M/6400 N/mm2 Note: 1 MPa = 1

N/mm2 Then 1.5

= σmax / σave = 90/[3M/6400)]

, 3M

= (90)(6400)/1.5 =

384,000 So M

= 128,000 N mm =

128 Nm (result) |

| Return to Notes on Solid Mechanics |

|---|

Copyright © 2019 Richard C. Coddington

All rights reserved.