Torsion

of a Circular Bar

|

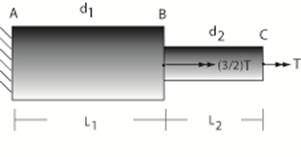

Example: The stepped shaft ABC

shown below has a material with shearing modulus of elasticity, G, of 11 x 106

psi. Two torques, -Ti and -(3/2)Ti lbin.

act on the shaft. The following data apply: T = 6000 lb in., L1 = 25 in., L2 = 18

in. d1 = 2.5 in., and d2 = 2 in. Find the maximum shear

stress in the stepped shaft. |

|

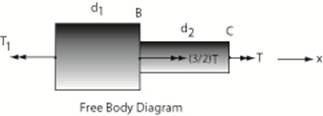

Strategy: Use a free body diagram to

determine the torque in each section of the stepped shaft. Then apply the relation for shear

stress τ = Tc/J

for each section to determine which shearing stress is

the maximum. For section 1 between A

and B: →ΣMx

= 0 - T1 + (3/2)T + T =

0 and for the data: T1 = 15000 lb in Now for the section

between A and B J1 =

π(d1/2)4 / 2 = 3.835 in4 τ1max = T1

(d1/2) / J1 = 15000(1.25)/3.835 =

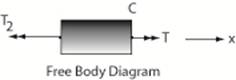

4890 psi →ΣMx

= 0 - T2 + T = 0 and for the data: T2 = 6000 lb in Now for the section

between B and C J2 =

π(d1/2)4 / 2 = 1.571 in4 τ2max = T2 (d2/2) / J2 = 6000(1.0)/1.571 =

3820 psi So τ1max = 4890

psi and τ2max = 3820 psi The maximum shearing

stress in the stepped shaft is then

4890 psi (in section 1).

(result) |

| Return to Notes on Solid Mechanics |

|---|

Copyright © 2019 Richard C. Coddington

All rights reserved.