|

|

Key Concepts: Flow of a

fluid in a pipe can be laminar, transitional, or turbulent. The pipe

is

assumed to be completely filled and

the fluid flowing in the pipe is assumed to be steady,

viscous,

and incompressible. Apply the

principles of conservation of mass (continuity equation)

and

conservation of energy apply to analyze pipe flow.

|

In a Nut Shell: Pipe

flow is a common way to transport fluid from one location to another.

Filling

your gas tank, supply of water from a water tower, plumbing in your home, and

transport

of

crude oil in Alaskan pipe lines are

just a few examples.

The

chart below summarizes a few key elements for laminar and turbulent pipe flow.

|

Pipe Flow (Single Pipe) |

|

Laminar |

Turbulent |

|

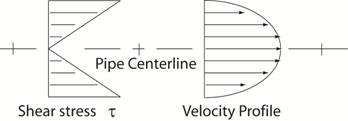

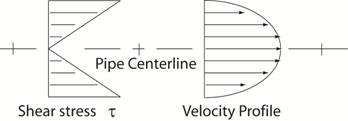

Linear Shear Stress Distribution

and

Parabolic Velocity Profile

|

Pressure Drop proportional to length

∆p/(1/2 ρV2) =

(L/D) φ{Re, ε/D}

Mass flow at each section along

pipe is constant

Energy In + Net Work Rate =

Energy Out + Loss

( between sections ) |

|

Shear stress, τ

= 2τw r/D

Velocity

Profile, u( r ) = Vc [ 1 – (2r/D)2 ]

Newtonian model for

shear stress gives

τ = -

μ du/dr

u( r ) =

[τw D / (4μ)] [ 1 –

(r/R)2 ]

Q =

[(πD4)/128 ] ∆P/μL

|

Friction

and various fittings in

pipes

results in energy loss.

Major

loss occurs along a length of

pipe

between sections.

Minor

losses occur at elbows, tees,

valves,

bends, etc

Further

discussion follows. |

Click

here to continue discussion. |